TBF™ Technology

The TBF™ series is a Transformer Based Power Filter, a new technology in power conditioning and the most effective solution to power quality problems. This is a device used between the electrical outlet and any electronic equipment, such as a computer, telecommunications or medical, copier, fax, POS system, or laser printer. The TBF™ series is a piece of equipment which conditions the power and protects the connected electronic equipment against lightning, EMI and RFI noise, low voltage and high voltage spikes, and transients. This device brings any spike from 1 to 6,000 volts to below 10 volts between hot and neutral, and to less than 0.5 volt between neutral ground.

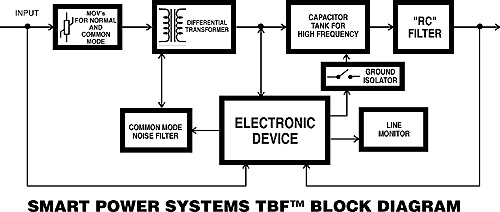

The block diagram illustrates the different circuits, which have been used in the TBF™. By using a differential transformer and capacitors, the TBF™ acts as a “line conditioning” electric filter (low pass filter). This unit filters both normal-mode and common-mode noise.

For common-mode noise filtration, it uses a differential transformer, which performs as a series inductor along with the capacitor between neutral and ground. Normally, the larger the capacitor used between neutral and ground, the greater the filtration of the output voltage of a spike or noise will become.

Safety guidelines set by Underwriters Laboratories Inc. in their code UL 1449 dictate the amount of current that can pass from line to ground through the capacitor or MOVs. The UL standard states that if by wrong wiring, line and neutral polarity is reversed or if the ground wire is disconnected, the amount of current which passes from line or neutral to ground, should be less than 0.5 milliamperes. This is called “ leakage current.”

In a surge suppressor or power filter, leakage current is a result of two things:

1. The MOVs that are used between line to ground and neutral to ground are such that the amount of the MOV leakage current is very small (0.05 0.15mA).

2. The other cause of leakage current is due to a capacitor being used between neutral and ground for neutral and ground filtration. As the value of the capacitor is increased, the leakage current becomes higher. At the same time we use a higher value capacitor when more filtration is required. Since the leakage current should be less than 0.5 mA, the value of the capacitor should be limited, which in turn limits and does not allow the device to achieve the needed filtration. In order to solve the above problem, we have designed a circuit that we call the process control board. Our device and its processor circuit are patented.